Fluids with Suspended Particles or Bubbles

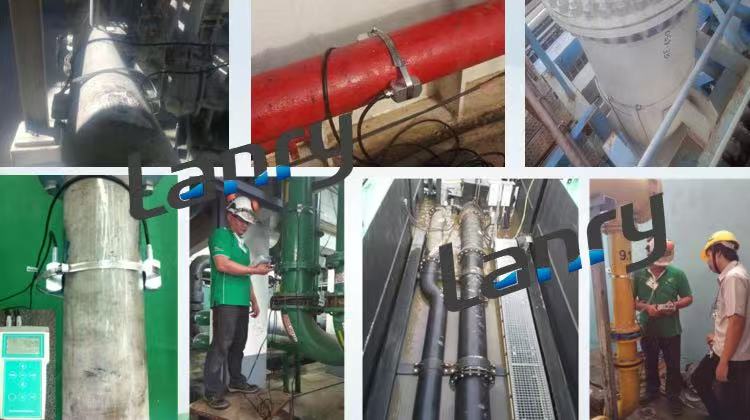

Doppler ultrasonic flow meters are particularly well - suited for measuring the flow of fluids that contain suspended solids or gas bubbles. In industrial processes such as mining, where slurry (a mixture of water and solid particles) is transported through pipelines, these meters can accurately measure the flow rate. The solid particles in the slurry, which can range from fine powders to relatively large grains, act as reflectors for the ultrasonic waves. As the slurry moves, the particles cause a Doppler shift in the frequency of the reflected ultrasonic signals. Similarly, in wastewater treatment plants, the presence of various suspended organic matter and solid debris allows the Doppler ultrasonic flow meters to function effectively. The meters can handle the complex and often changing composition of wastewater, providing reliable flow rate measurements for proper treatment process control. In the oil and gas industry, during the production of oil, the fluid often contains gas bubbles. Doppler ultrasonic flow meters can accurately measure the flow of such multiphase fluids, taking into account the contribution of both the liquid and gas phases to the overall flow.

Flows in Open Channels

These flow meters are also applicable in open - channel flows, such as in rivers, irrigation canals, and stormwater drains. In river monitoring, Doppler ultrasonic flow meters can be installed on bridges or riverbanks. The natural flow of the river, which may carry sediment particles, provides the necessary scatterers for the ultrasonic waves. By measuring the Doppler shift of the reflected waves, the flow velocity at different points across the river cross - section can be determined. This data can then be used to calculate the volumetric flow rate of the river. In irrigation systems, where water is distributed through open canals, Doppler ultrasonic flow meters help in precisely measuring the amount of water being delivered to the fields. This is crucial for efficient water management and ensuring that crops receive the appropriate amount of water. In urban stormwater management, the meters can be used to monitor the flow of stormwater in drains, which often contains debris and sediment, enabling better planning and management of flood prevention measures.

High - Velocity Flows

Doppler ultrasonic flow meters can effectively measure high - velocity fluid flows. In industrial applications like hydroelectric power plants, where water is discharged at high speeds through penstocks to drive turbines, these meters can accurately measure the flow rate. The high - velocity water contains small air bubbles entrained during the process, which serve as reflectors for the ultrasonic waves. The ability of the Doppler ultrasonic flow meters to handle high - velocity flows without significant loss of accuracy makes them a valuable tool in such power - generation scenarios. In some chemical processes, high - velocity flows of corrosive or abrasive fluids are common. The non - intrusive nature of Doppler ultrasonic flow meters (as they are typically installed externally on the pipe or channel) makes them suitable for measuring these high - velocity flows, as they are not subject to the wear and tear that would affect traditional in - line flow meters.

Harsh Environmental Conditions

They are also capable of operating in harsh environmental conditions. In industrial settings with extreme temperatures, such as in steel mills where the ambient temperature can be very high, or in Arctic oil and gas operations where temperatures are extremely low, Doppler ultrasonic flow meters can function reliably. Their robust construction and the fact that they do not require direct contact with the fluid (except for the ultrasonic transducers which can be designed to withstand harsh conditions) make them suitable for these environments. In addition, in areas with high levels of electromagnetic interference, such as near large electrical transformers or in industrial plants with a large number of electrical motors, Doppler ultrasonic flow meters can be shielded to ensure accurate operation. They can also be used in environments where the fluid is corrosive, as long as the ultrasonic transducers are made of appropriate corrosion - resistant materials.

In conclusion, Doppler ultrasonic flow meters are highly adaptable and find applications in a wide range of working conditions, from handling fluids with suspended matter to operating in harsh environments and measuring high - velocity flows in various industrial and environmental scenarios.

Post time: Feb-24-2025