Ultrasonic flow meters have found widespread use in various industries, including wastewater management, due to their versatility, non-invasive measurement capabilities, and ease of installation. In wastewater applications, accurate flow measurement is essential for ensuring proper system functioning, regulatory compliance, and efficient treatment processes. Below is an overview of the role of ultrasonic flow meters in wastewater systems and their key benefits.

1. Principle of Operation in Wastewater Systems

Ultrasonic flow meters function by transmitting high-frequency sound waves through the fluid in a pipeline. These sound waves travel at different speeds depending on the flow direction. By measuring the difference in time it takes for the sound waves to travel upstream and downstream, the flow velocity is calculated. This data is then used to determine the flow rate.

There are two main types of ultrasonic flow meters used in wastewater applications:

- Transit-Time Ultrasonic Flow Meters: These measure the time difference between the transmitted and received sound waves traveling with and against the flow direction. They are most commonly used for clean and slightly contaminated fluids.

- Doppler Ultrasonic Flow Meters: These meters work by detecting frequency shifts caused by particles or bubbles in the fluid. They are used for wastewater containing suspended solids, air bubbles, or other irregularities that could interfere with transit-time measurements.

2. Advantages of Ultrasonic Flow Meters in Wastewater

-

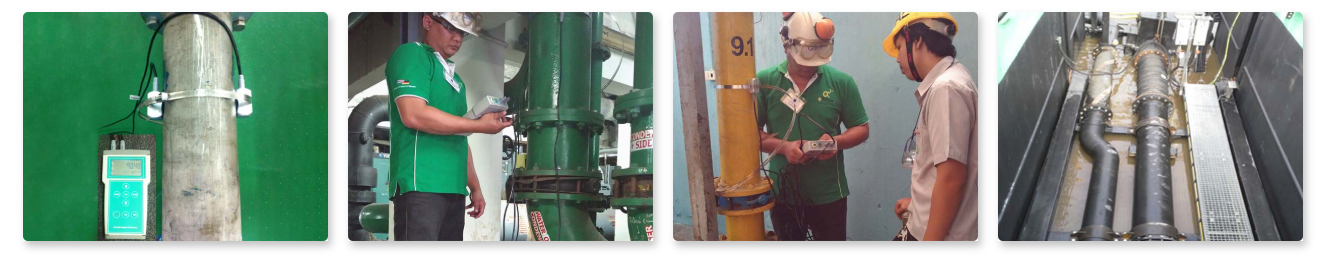

Non-Invasive Measurement:

One of the most significant advantages of ultrasonic flow meters is their non-invasive nature. Clamp-on models can be installed on the exterior of existing pipes, without the need for cutting or shutting down the system. This feature is especially beneficial in wastewater treatment facilities, where maintaining continuous operations is crucial. -

Minimal Maintenance:

Ultrasonic flow meters have no moving parts, reducing the likelihood of mechanical wear and tear. This makes them low-maintenance and more reliable than other types of flow meters, such as mechanical meters, in wastewater applications where sediment and debris can cause frequent damage. -

Versatility:

Ultrasonic flow meters are highly adaptable to different types of wastewater, including those with varying viscosities, temperatures, and contaminant levels. Doppler ultrasonic flow meters can even be used in highly contaminated or turbulent wastewater streams that contain large particles, suspended solids, or gas bubbles. -

Accuracy and Reliability:

Ultrasonic flow meters can deliver high accuracy even in fluctuating flow conditions, which is often the case in wastewater systems where flow rates can vary significantly. Advanced models offer accuracies of ±1% or better, which is critical for monitoring and controlling wastewater flows, especially in applications where precise measurements are needed for regulatory compliance. -

Cost-Effective:

In terms of installation, ultrasonic flow meters are often more cost-effective than other types of flow meters, such as electromagnetic meters or mechanical meters. They can be installed quickly without interrupting the flow of wastewater, reducing downtime and operational costs.

3. Applications in Wastewater Treatment

-

Flow Measurement in Sewer Systems:

Ultrasonic flow meters are commonly used in municipal and industrial sewer systems to monitor the flow of wastewater. Accurate flow measurement is essential for managing sewage treatment plants, ensuring the efficient treatment of wastewater, and preventing overflows. By measuring flow rates at various points in the system, operators can optimize the treatment processes and make informed decisions about resource allocation. -

Pump and Lift Station Monitoring:

In wastewater systems, pumps and lift stations are integral to moving wastewater through the treatment process. Ultrasonic flow meters can monitor the flow at these critical points, helping to ensure pumps are operating at optimal efficiency. This monitoring helps prevent over-pumping or under-pumping, both of which can lead to system failures or inefficiencies. -

Stormwater Management:

During heavy rainfall, stormwater runoff can overload municipal sewer systems, leading to potential flooding or discharge of untreated wastewater into rivers and oceans. Ultrasonic flow meters can be used to measure the flow of stormwater in real time, allowing operators to monitor and control the volume of water entering treatment facilities, and to make necessary adjustments for more efficient stormwater management. -

Monitoring of Effluent Discharge:

Wastewater treatment plants are required to meet specific discharge limits set by environmental regulations. Ultrasonic flow meters help ensure that effluent discharge from the plant complies with local or international standards by providing real-time monitoring of flow rates. Accurate flow measurements are essential for compliance reporting and for preventing fines due to non-compliance. -

Sludge and Biogas Monitoring:

In some advanced wastewater treatment processes, such as anaerobic digestion, ultrasonic flow meters can be used to monitor the flow of biogas generated from organic waste. Similarly, the flow of sludge, which is a byproduct of wastewater treatment, can be monitored for efficient handling and disposal.

4. Challenges and Considerations

While ultrasonic flow meters offer many benefits in wastewater management, there are several factors to consider:

-

Presence of Solids and Bubbles:

In wastewater, suspended solids, air bubbles, and other contaminants can affect the accuracy of ultrasonic flow meters. Doppler ultrasonic flow meters are specifically designed to handle such conditions, but even these may require calibration adjustments depending on the size, type, and concentration of particles in the wastewater. -

Pipe Material and Condition:

The material and condition of the pipe can also impact the performance of ultrasonic flow meters. Corrosion, scale build-up, or irregular pipe surfaces may distort the sound waves and reduce accuracy. Regular inspection and maintenance of the pipes are essential for ensuring optimal measurement performance. -

Temperature and Fluid Composition:

Changes in the temperature and composition of the wastewater can influence the speed of sound in the fluid, which in turn affects the measurement accuracy. Advanced ultrasonic meters can compensate for these variations, but the installation and calibration process must account for these factors.

5. Future Trends

As the technology behind ultrasonic flow meters continues to improve, their applications in wastewater management will expand. Innovations such as wireless connectivity, integration with SCADA systems, and real-time data analysis are making ultrasonic flow meters an even more valuable tool in the monitoring and management of wastewater systems. These advancements will allow operators to make data-driven decisions in real time, improving efficiency, reducing costs, and ensuring environmental compliance.

Conclusion

Ultrasonic flow meters are increasingly used in wastewater management due to their non-invasive, low-maintenance, and accurate measurement capabilities. They are particularly effective in applications where the flow of wastewater needs to be continuously monitored, such as in sewer systems, lift stations, stormwater management, and effluent discharge monitoring. By offering flexibility and precision, ultrasonic flow meters help optimize wastewater treatment processes, ensure regulatory compliance, and improve the overall efficiency of wastewater infrastructure.

Post time: Jan-12-2025