1. Introduction

Doppler ultrasonic flow meters have become an essential tool in fluid flow measurement across various industries. Their unique operating principle, based on the Doppler effect, endows them with several distinct characteristics that make them highly suitable for a wide range of applications.

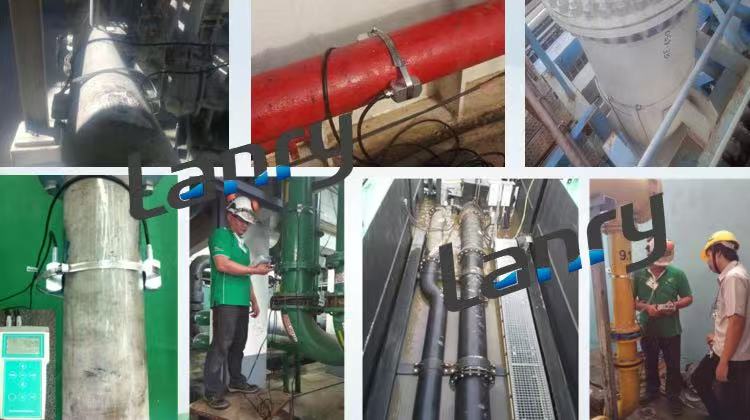

2. Non - Intrusive Measurement

One of the most prominent features of Doppler ultrasonic flow meters is their non - intrusive nature. Ultrasonic transducers are simply clamped onto the outer surface of the pipeline. This eliminates the need for any physical penetration into the pipe or disruption of the fluid flow. As a result, installation is relatively quick and easy, often requiring minimal downtime. For example, in a chemical plant where the pipelines carry highly corrosive or toxic fluids, this non - intrusive installation method is extremely beneficial. It reduces the risk of leaks and contamination that could occur if the pipeline were to be opened for the installation of an in - line flow meter.

3. Applicability to Fluids with Suspended Particles or Bubbles

Doppler ultrasonic flow meters are particularly well - suited for measuring the flow of fluids that contain suspended solids or gas bubbles. The ultrasonic waves emitted by the transducer are reflected by these particles or bubbles in the fluid. The Doppler shift in the frequency of the reflected waves, caused by the movement of the reflecting objects with the fluid flow, is then detected and used to calculate the fluid velocity. This makes them ideal for applications such as in wastewater treatment plants, where the sewage contains a variety of suspended organic matter and solid particles. In the oil and gas industry, during the production of oil, the fluid often contains gas bubbles, and Doppler ultrasonic flow meters can accurately measure the flow rate of this multiphase fluid.

4. Wide Flow Range

These flow meters can handle a broad range of flow rates. They are capable of accurately measuring both very low and extremely high flow velocities. This wide flow range adaptability makes them suitable for diverse applications. In a small - scale laboratory setting, where precise measurement of minute fluid flows is required, Doppler ultrasonic flow meters can provide accurate readings. On the other hand, in large - scale industrial processes, such as in power plants where high - volume water or steam flows need to be measured, these meters can also perform reliably. Their ability to cover such a wide flow range without significant loss of accuracy is a major advantage.

5. High - Speed Response

Doppler ultrasonic flow meters offer a high - speed response, enabling them to quickly detect changes in fluid flow. This is crucial in applications where real - time monitoring of flow rate variations is essential. For example, in a manufacturing process where the flow of raw materials needs to be precisely controlled, any sudden changes in the flow rate can be immediately detected by the Doppler ultrasonic flow meter. This allows for rapid adjustments to be made to the process, ensuring consistent product quality and efficient operation.

6. No Moving Parts

Another advantage of Doppler ultrasonic flow meters is that they have no moving parts within the fluid flow path. This significantly reduces the risk of mechanical wear and tear, which is a common issue with traditional flow meters that rely on moving components like turbines or gears. With no moving parts, the maintenance requirements are minimal, and the lifespan of the flow meter is extended. This makes them a cost - effective choice in the long run, as there is no need for frequent replacement of worn - out parts or costly maintenance procedures.

7. Resistance to Harsh Environments

Doppler ultrasonic flow meters are designed to withstand harsh environmental conditions. They can operate in a wide temperature range, from extremely cold environments in Arctic oil and gas operations to high - temperature settings in steel mills or power plants. Additionally, they are often resistant to electromagnetic interference, which is common in industrial environments with a large number of electrical motors, transformers, and other electrical equipment. Their robust construction and the non - contact measurement method make them suitable for use in areas where the fluid being measured may be corrosive, as the transducers are not in direct contact with the fluid.

8. Easy Installation and Calibration

The installation of Doppler ultrasonic flow meters is relatively straightforward. The transducers can be easily clamped onto the pipe, and in many cases, no special tools or complex procedures are required. Calibration of these flow meters is also relatively simple. Once installed, they can be calibrated using standard calibration procedures, and in some cases, they can be self - calibrated based on known fluid properties and the geometry of the pipeline. This ease of installation and calibration makes them accessible to a wide range of users, even those with limited technical expertise.

In conclusion, Doppler ultrasonic flow meters offer a combination of features that make them highly versatile and reliable for fluid flow measurement. Their non - intrusive nature, ability to handle fluids with suspended matter, wide flow range, high - speed response, lack of moving parts, resistance to harsh environments, and easy installation and calibration make them a preferred choice in numerous industrial, environmental, and scientific applications.

Post time: Mar-03-2025