Doppler Ultrasonic Flow Meters are revolutionizing the way industries measure and monitor fluid flow. These advanced devices use the Doppler Effect to provide accurate, non-invasive flow measurements, making them indispensable for a wide range of applications. In this article, we will explore the key concepts, benefits, and applications of ultrasonic flow meters, highlighting their ability to deliver real-time flow monitoring with exceptional accuracy and ease.

What is the Doppler Effect in Flow Measurement?

At the core of a Doppler Ultrasonic Flow Meter is the Doppler Effect — a phenomenon in which the frequency of an ultrasonic wave changes when it reflects off moving particles or bubbles within a fluid. By analyzing this frequency shift, the device can calculate the flow velocity of the fluid, whether it’s a liquid or a gas. This makes Doppler Ultrasonic Flow Meters highly effective for monitoring fluid flow in various pipes and conduits.Unlike traditional mechanical or turbine-based flow meters, Doppler ultrasonic meters do not require physical contact with the fluid. Instead, they use sound waves to measure the flow, offering significant advantages in terms of non-invasive flow measurement. This non-contact method not only reduces maintenance needs but also ensures that there are no disruptions or risks of contamination to the fluid being measured.

Key Features and Benefits

1.Non-Invasive Flow Measurement

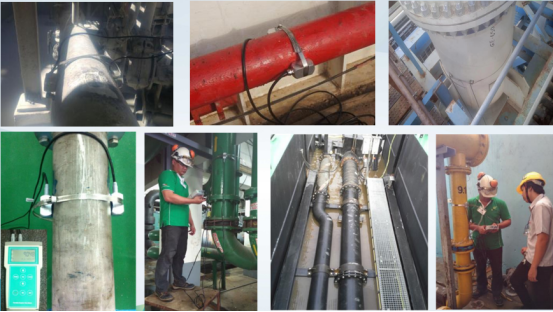

One of the most significant advantages of Doppler ultrasonic meters is their ability to measure flow without any intrusion into the pipe or vessel. The sensors are mounted on the outside of the pipe, making installation easier and avoiding the need for cutting or welding. This reduces both downtime and maintenance costs.

2.Real-Time Flow Monitoring

Real-time flow monitoring is critical in many industries, including water treatment, oil and gas, and food processing. Doppler ultrasonic flow meters offer instant data on the flow velocity, providing real-time feedback for process optimization, control, and troubleshooting.

3.High Accuracy and Reliability

These meters deliver highly accurate flow measurements, even in challenging environments. The technology can measure flow rates of both clear and opaque fluids, including liquids with suspended particles or gas bubbles. This makes them suitable for a wide range of fluids, from wastewater to chemicals.

4.Wide Range of Applications

Doppler ultrasonic flow meters are versatile, capable of handling a variety of applications such as pipe flow detection in pipelines, velocity profile analysis in open channels, and liquid flow measurement in industrial processes. Whether measuring water flow in municipal systems or monitoring the flow of oil in refineries, these devices are crucial for ensuring efficiency and safety.

5.Minimal Maintenance and Long Lifespan

The lack of moving parts reduces the wear and tear on the device, allowing for minimal maintenance. This is a key advantage for industries that require continuous monitoring over extended periods, such as water treatment plants or chemical processing facilities.

6.Flow Calibration and Customization

Modern Doppler ultrasonic meters often come with the ability to calibrate for different types of fluid or pipe configurations. This allows for flow calibration based on specific system requirements, ensuring that the meter provides the most accurate readings under varying conditions.

How Doppler Ultrasonic Flow Meters Work

The working principle of Doppler ultrasonic flow meters is simple yet effective. The system uses two transducers: one to send ultrasonic waves into the fluid and another to receive the reflected waves. When particles or bubbles within the fluid move, they shift the frequency of the returning sound waves. The Doppler shift is directly proportional to the flow velocity of the fluid.

By measuring the frequency shift, the flow meter calculates the flow velocity and uses this data to determine the overall flow rate in the pipeline or channel. This approach allows for precise measurements in a variety of conditions, even with liquids containing suspended solids or gas bubbles, which can pose challenges for other flow measurement methods.

Applications of Doppler Ultrasonic Flow Meters

1.Water and Wastewater Management

In municipal and industrial water treatment facilities, Doppler ultrasonic flow meters are used for real-time flow monitoring to measure water flow in pipes and sewage systems. These meters help maintain water quality, manage resources, and ensure compliance with regulatory standards.

2.Oil and Gas Industry

The oil and gas industry relies heavily on accurate flow velocity measurement to ensure safe and efficient operations. Doppler ultrasonic meters are widely used to monitor the flow of crude oil, natural gas, and chemicals in pipelines and refineries, providing essential data for flow calibration and system maintenance.

3.Chemical Processing

Doppler ultrasonic flow meters are employed in the chemical industry for measuring the flow of liquids and gases in reactors, mixers, and other critical systems. Their ability to handle liquids with suspended solids or gas bubbles makes them ideal for this sector.

4.Food and Beverage

In food processing, where hygiene and contamination control are paramount, Doppler ultrasonic flow meters provide non-invasive flow measurement of liquids like milk, juice, and sauces. Their easy installation and reliable performance make them an excellent choice for maintaining process efficiency.

5.Energy Sector

For energy production facilities, particularly those in the renewable energy sector, these meters offer a cost-effective solution for measuring fluid flows in heat exchangers, turbines, and cooling systems. Their precision helps ensure that energy production remains optimal.

In conclusion,Doppler Ultrasonic Flow Meters provide a reliable, accurate, and cost-effective solution for flow velocity measurement and flow rate determination in a wide range of industries. With their non-invasive measurement capabilities, real-time monitoring, and minimal maintenance requirements, these devices are indispensable tools for improving operational efficiency, ensuring safety, and reducing downtime.Whether you’re working in water treatment, oil and gas, or food processing, Doppler ultrasonic flow meters offer the versatility and precision necessary to keep your systems running smoothly. By understanding how these meters work and the benefits they offer, industries can make informed decisions about adopting this technology for their flow measurement needs.

Post time: Jan-02-2025