Doppler ultrasonic flowmeters have become indispensable in fluid measurement across industries, offering non-intrusive, low-maintenance solutions for challenging environments. Unlike transit-time ultrasonic meters, which require clean fluids, Doppler meters rely on the scattering of ultrasonic waves by particulates or bubbles in the fluid to calculate flow velocity. This fundamental mechanism imposes specific requirements on pipeline impurities, making understanding their role critical for optimal meter performance.

Working Principle and the Role of Impurities

The Doppler effect forms the basis of these meters: a transducer emits ultrasonic waves into the fluid, and particles or gas bubbles (referred to as "scatterers") suspended in the flow reflect these waves back to a receiver. The frequency shift between the transmitted and reflected waves (Doppler shift) is directly proportional to the fluid’s velocity. Thus, impurities are not contaminants but essential components for measurement—without sufficient scatterers, the Doppler effect cannot occur, rendering the meter ineffective.

Critical Requirements for Pipeline Impurities

1. Particle Concentration

- Minimum Threshold: Doppler meters require a minimum concentration of scatterers (typically ≥100 ppm for solid particles or ≥0.1% volume fraction for bubbles). Below this, the reflected signal becomes too weak to detect accurately, leading to unstable or unreliable readings.

- Optimal Range: For most applications, a concentration of 500–5,000 ppm (solid particles) or 1–5% bubble content yields the most consistent results. Higher concentrations may cause signal interference due to excessive scattering, reducing measurement precision.

2. Particle Size and Distribution

- Effective Size Range: Scatterers must be large enough to reflect ultrasonic waves but small enough to flow with the fluid. Typically, particles or bubbles between 10 μm and 3 mm are ideal. Microscopic particles (e.g., <1 μm) may not reflect signals strongly, while large solids (e.g., >5 mm) can cause flow disturbances or blockages, distorting velocity profiles.

- Uniform Distribution: Non-uniform particle distribution (e.g., settling solids in low-velocity pipes) can create "dead zones" with insufficient scatterers, leading to measurement errors. Turbulent flow or proper pipeline design (e.g., straight inlet sections) helps maintain homogeneous particle suspension.

3. Particle Type and Acoustic Properties

- Acoustic Contrast: Scatterers must have a different acoustic impedance than the base fluid. For example, air bubbles in water or solid particles in oil create strong reflection interfaces, while dissolved solids (e.g., salts) that do not form discrete particles are ineffective.

- Non-Abrasive Materials: Highly abrasive particles (e.g., sand in slurry pipelines) can damage transducer surfaces over time, reducing meter longevity. Protective coatings or transducer placement (e.g., angled installation) may mitigate this risk.

4. Fluid Turbulence and Velocity

- Turbulence Aids Scattering: Moderate turbulence enhances particle dispersion, improving signal consistency. However, excessive turbulence (e.g., in valves or elbows) can create chaotic flow patterns, causing erratic Doppler shifts.

- Minimum Velocity: Flow velocity must exceed a threshold (typically ≥0.1 m/s) to ensure particle movement and reliable signal detection. At very low velocities, particles may settle, reducing effective scatterer concentration.

Challenges of Improper Impurity Conditions

- Inadequate Scatterers: Low particle concentration (e.g., clean water) renders Doppler meters unsuitable, as no measurable signal is generated. In such cases, transit-time ultrasonic or mechanical meters may be more appropriate.

- Excessive Scatterers: Highly dense slurries or frothy fluids can cause "signal congestion," where multiple reflections interfere with each other, leading to noisy data. Advanced signal processing algorithms (e.g., adaptive filtering) can help mitigate this issue.

- Cohesive Particles: Sticky or agglomerating particles (e.g., sludge) may adhere to pipe walls or transducers, reducing effective scatterer mobility and introducing measurement bias. Regular pipeline cleaning or anti-fouling coatings are recommended in such scenarios.

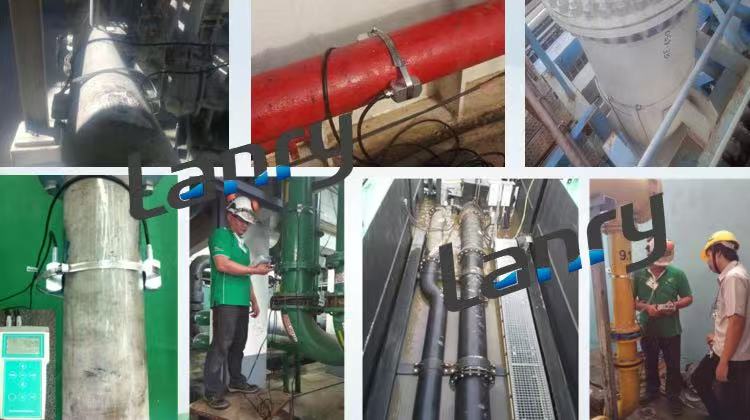

Practical Applications and Mitigation Strategies

- Wastewater Treatment: Doppler meters excel here due to high solids content (e.g., suspended solids in primary clarifiers). Regular maintenance to prevent transducer fouling is critical.

- Industrial Slurries: In mining or chemical plants, ensuring particle size distribution (via sieving or cyclone separators) and using wear-resistant transducers optimize performance.

- Gas-Liquid Two-Phase Flows: In oil and gas pipelines, bubble fraction must be monitored to avoid signal instability. Multi-path Doppler designs or combined Doppler-transit-time meters can improve accuracy in such complex flows.

Conclusion

Doppler ultrasonic flowmeters thrive in applications with dirty, turbulent, or two-phase flows, but their performance is inherently tied to pipeline impurity characteristics. By ensuring proper particle concentration, size, distribution, and acoustic properties, users can unlock the full potential of these meters for reliable, long-term flow measurement. As technology advances—with innovations in signal processing and transducer design—Doppler meters are poised to tackle even more challenging fluid environments, further expanding their utility in industrial and municipal systems.

Post time: Apr-25-2025