Doppler ultrasonic flowmeters are valuable instruments for measuring fluid flow in a wide range of applications. However, several factors can lead to inaccurate or sub - optimal performance of these flowmeters.

1. Fluid Properties

-

Gas Content: Fluids with a high gas content can pose significant challenges. In a pipeline, gas bubbles act as scatterers of ultrasonic waves. When gas is present in the liquid, the ultrasonic signal sent by the transducer encounters these gas bubbles. Since the acoustic impedance of gas is much lower than that of the liquid, a large portion of the ultrasonic energy is reflected or scattered when it hits the gas - liquid interface. This disrupts the signal received by the sensor, making it difficult for the flowmeter to accurately detect the Doppler shift caused by the moving fluid. As a result, the measured flow rate can deviate significantly from the actual value.

-

Particle Concentration and Size: Doppler ultrasonic flowmeters rely on the reflection of ultrasonic waves from particles or inhomogeneities in the fluid. If the particle concentration is too low, there may not be enough reflecting elements to generate a strong enough signal for accurate measurement. Conversely, if the particle concentration is too high, multiple reflections can occur, leading to signal interference. Additionally, the size of the particles matters. Small particles may not reflect the ultrasonic waves effectively, while large particles can cause excessive scattering and absorption of the signal. The optimal particle size range for accurate measurement depends on the frequency of the ultrasonic transducer used in the flowmeter.

-

Viscosity: High - viscosity fluids can slow down the movement of particles within the fluid. Since the Doppler shift is related to the velocity of the reflecting particles, a decrease in particle velocity due to high viscosity can lead to an underestimation of the flow rate. Moreover, high - viscosity fluids may cause additional damping of the ultrasonic waves, reducing the signal - to - noise ratio and further degrading the measurement accuracy.

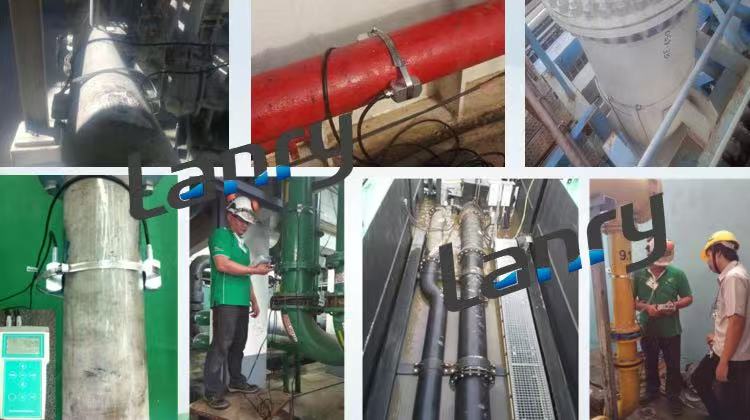

2. Installation - Related Factors

- Pipe Geometry and Sensor Placement: The geometry of the pipeline plays a crucial role. If the pipe has bends, elbows, or sudden changes in diameter near the installation location of the flowmeter, the flow profile can be distorted. This non - uniform flow can cause the ultrasonic signal to interact with the fluid in an unpredictable way. For example, in a pipe bend, the fluid velocity distribution is skewed, and the Doppler shift measured by the sensor may not accurately represent the average flow velocity across the entire cross - section of the pipe. Additionally, incorrect sensor placement, such as mounting the sensor too close to a pipe fitting or at an improper angle, can lead to inaccurate measurements. The sensor should be installed in a straight section of the pipe where the flow is fully developed to ensure reliable results.

- Pipe Material and Wall Thickness: Different pipe materials have different acoustic properties. For instance, some materials may absorb or attenuate ultrasonic waves more than others. If the pipe material has a high acoustic absorption coefficient, the strength of the ultrasonic signal reaching the receiving sensor will be reduced. Similarly, a thick pipe wall can also cause significant signal attenuation. This can make it difficult for the flowmeter to detect the Doppler shift accurately, especially in cases where the original signal strength is already marginal.

3. Operational Conditions

- Flow Velocity Range: Doppler ultrasonic flowmeters are designed to operate within a specific flow velocity range. If the flow velocity is too low, the Doppler shift may be too small to be accurately detected by the sensor. On the other hand, if the flow velocity is too high, the signal may become saturated, and the flowmeter may not be able to accurately measure the Doppler shift. In both cases, the measured flow rate will be inaccurate.

- Temperature Variations: Temperature can affect the properties of both the fluid and the ultrasonic transducer. Changes in fluid temperature can alter its density, viscosity, and the speed of sound within the fluid. These changes can in turn affect the propagation of ultrasonic waves and the Doppler shift measurement. Additionally, temperature variations can also impact the performance of the transducer itself. For example, extreme temperatures can cause the transducer to expand or contract, changing its resonant frequency and potentially leading to inaccurate measurements.

In conclusion, a variety of factors related to fluid properties, installation, and operational conditions can cause Doppler ultrasonic flowmeters to provide inaccurate measurements. Understanding and properly addressing these factors are essential for ensuring the reliable operation of these flowmeters in practical applications.

Post time: Mar-10-2025