Ultrasonic flowmeters are widely used for measuring the flow of liquids and gases in pipelines. Among the different types of ultrasonic flowmeters, Transit-Time Inline and Transit-Time Clamp-On are two of the most commonly used solutions. However, choosing the right one can be a challenge, especially when dealing with aged pipelines, non-uniform pipe material, and other challenging conditions. In this article, we’ll compare these two types of ultrasonic flowmeters to help you make an informed decision.

1. Understanding the Two Types of Transit-Time Ultrasonic Flowmeters

Transit-Time Inline Ultrasonic Flowmeter

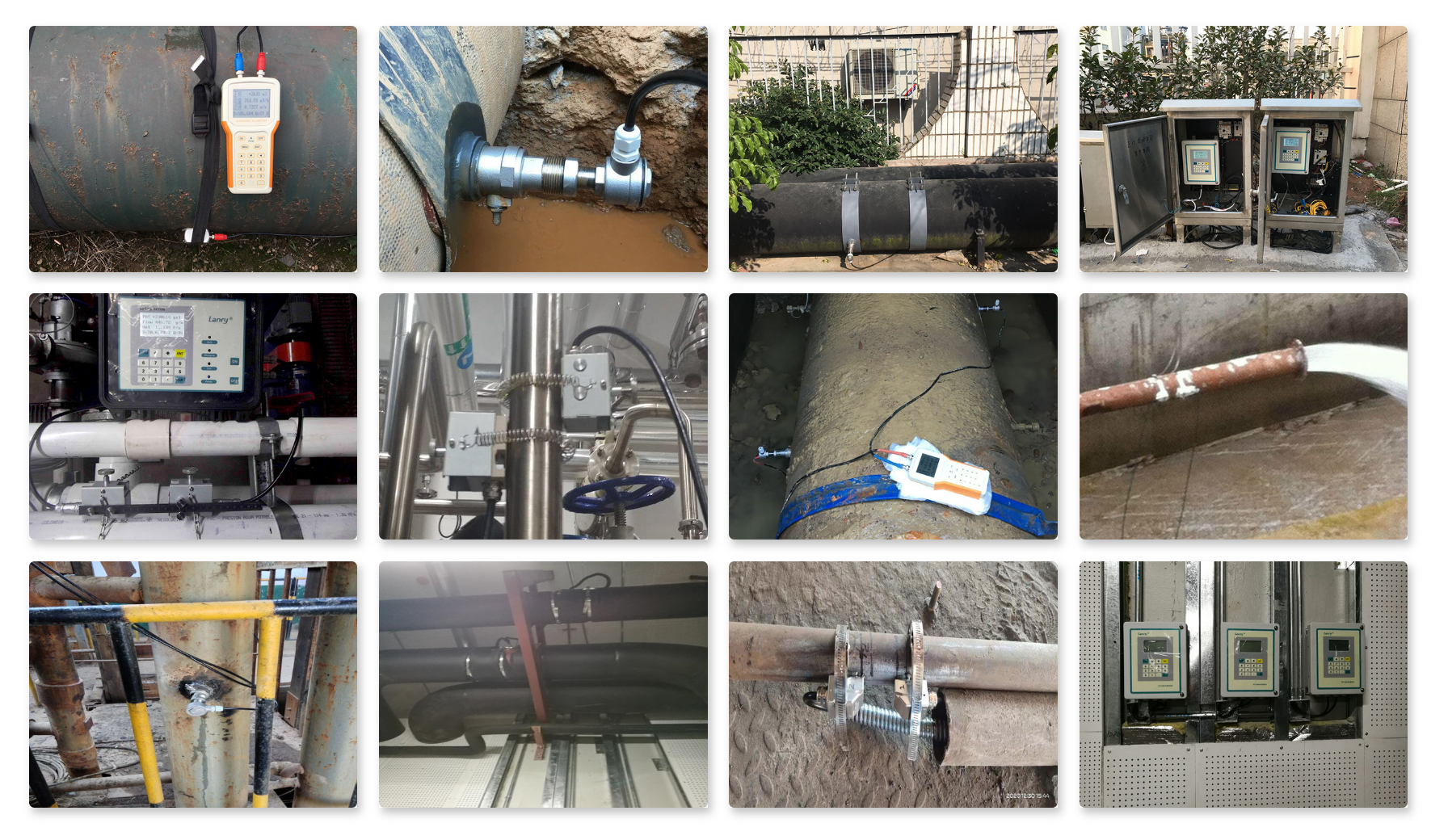

A Transit-Time Inline Ultrasonic Flowmeter is installed directly into the pipeline. It requires the pipeline to be cut open for installation, where ultrasonic sensors are placed inside the pipe to measure the time it takes for an ultrasonic signal to travel between them. This method provides high accuracy because the sensors are directly in contact with the fluid flow.

Key Features:

- Requires pipe modification (cutting and installing the sensor inside the pipe).

- High accuracy, especially for stable, well-maintained pipelines.

- Suitable for larger pipes or industrial applications with permanent installation.

Transit-Time Clamp-On Ultrasonic Flowmeter

A Transit-Time Clamp-On Ultrasonic Flowmeter is non-intrusive and is attached externally to the pipeline. It measures the time taken for ultrasonic waves to pass through the pipe and the fluid inside. The clamp-on installation avoids the need for cutting the pipe, making it a much simpler, faster, and less invasive solution.

Key Features:

- No pipe modification required.

- Quick installation and easy to relocate.

- Suitable for a variety of pipe sizes and materials.

- Ideal for temporary measurements or when there’s a need for frequent portability.

2. Factors to Consider When Choosing Between Inline and Clamp-On Flowmeters

When choosing between inline and clamp-on flowmeters, several factors need to be considered. These include the condition of the pipeline, type of fluid, and installation requirements. Here’s how these factors impact your decision:

Aged Pipelines

Aged pipelines are often corroded, damaged, or have uneven surface textures, which can interfere with the performance of inline flowmeters. The inline option requires modifications to the pipeline, and in such cases, the risk of further damaging the pipeline during installation increases. Additionally, corrosion can affect the accuracy of the flow measurement, making maintenance and installation costlier.

In this case, the Transit-Time Clamp-On Flowmeter is often a better option. Since it does not require any modification or penetration of the pipe, it is less likely to exacerbate issues in aged pipelines. It is also easier to install without the need for welding or cutting, which is a significant advantage when working with older systems.

Non-Uniform Pipe Materials

In some cases, the material of the pipe may not be uniform, which can lead to irregular internal surfaces. These inconsistencies can cause interference with the ultrasonic signals used in inline flowmeters, especially if the pipe has layers of different materials, such as steel, coatings, or insulation.

For non-uniform pipes, a Clamp-On Ultrasonic Flowmeter would be more effective, as it can accommodate a wider range of pipe materials and thicknesses without affecting the accuracy of the measurement. The clamp-on method is less sensitive to variations in pipe materials, as it measures the overall time of flight of the ultrasonic waves rather than relying on direct contact with the pipe’s interior.

Pipe Size and Flow Conditions

Inline flowmeters often perform better when installed on pipes of larger diameter or in systems with stable, uniform flow conditions. However, if the pipe diameter is smaller or the flow conditions are more variable, such as in the case of fluctuating or turbulent flows, clamp-on flowmeters can be more suitable. They offer the flexibility to be installed in different locations along the pipe, allowing for measurements in areas where flow conditions are more stable.

Cost and Installation Complexity

Inline ultrasonic flowmeters require installation that typically involves cutting the pipe and welding or sealing sensors into place. This can lead to higher installation costs, potential downtime, and maintenance work. Furthermore, inline installation may not be ideal for temporary or low-budget applications.

In contrast, clamp-on ultrasonic flowmeters have a lower installation cost and can be installed without interrupting the flow of the fluid. They are easier to use, quicker to install, and allow for non-invasive monitoring. This makes them ideal for applications where time or budget constraints are a concern, or where temporary or portable monitoring is required.

3. Which Flowmeter Is Right for You?

Based on the conditions you’ve mentioned — aged pipelines and non-uniform pipe materials — a Transit-Time Clamp-On Ultrasonic Flowmeter may be the best option for you. Here's why:

- Non-intrusive measurement: It eliminates the need for invasive modifications to aging pipes, reducing the risk of causing damage during installation.

- Flexibility: It can handle non-uniform pipe materials without compromising measurement accuracy.

- Quick and easy installation: Ideal for situations where downtime is a concern, and the pipes are difficult or expensive to modify.

- Cost-effective: Because it doesn't require pipe cutting, welding, or other costly modifications, clamp-on systems generally offer a more affordable solution.

Conclusion

Selecting the right flowmeter depends on various factors, such as pipeline conditions, pipe material, and the specific requirements of the application. When faced with aged pipelines or non-uniform pipe materials, a Transit-Time Clamp-On Ultrasonic Flowmeter offers a practical, reliable, and cost-effective solution. If you are looking for an easy-to-install, non-invasive, and versatile flow measurement option, our ultrasonic flowmeters are designed to meet your needs.

Please feel free to contact us if you'd like more information on how our ultrasonic flowmeters can benefit your operations!

Post time: Feb-14-2025