1. Introduction

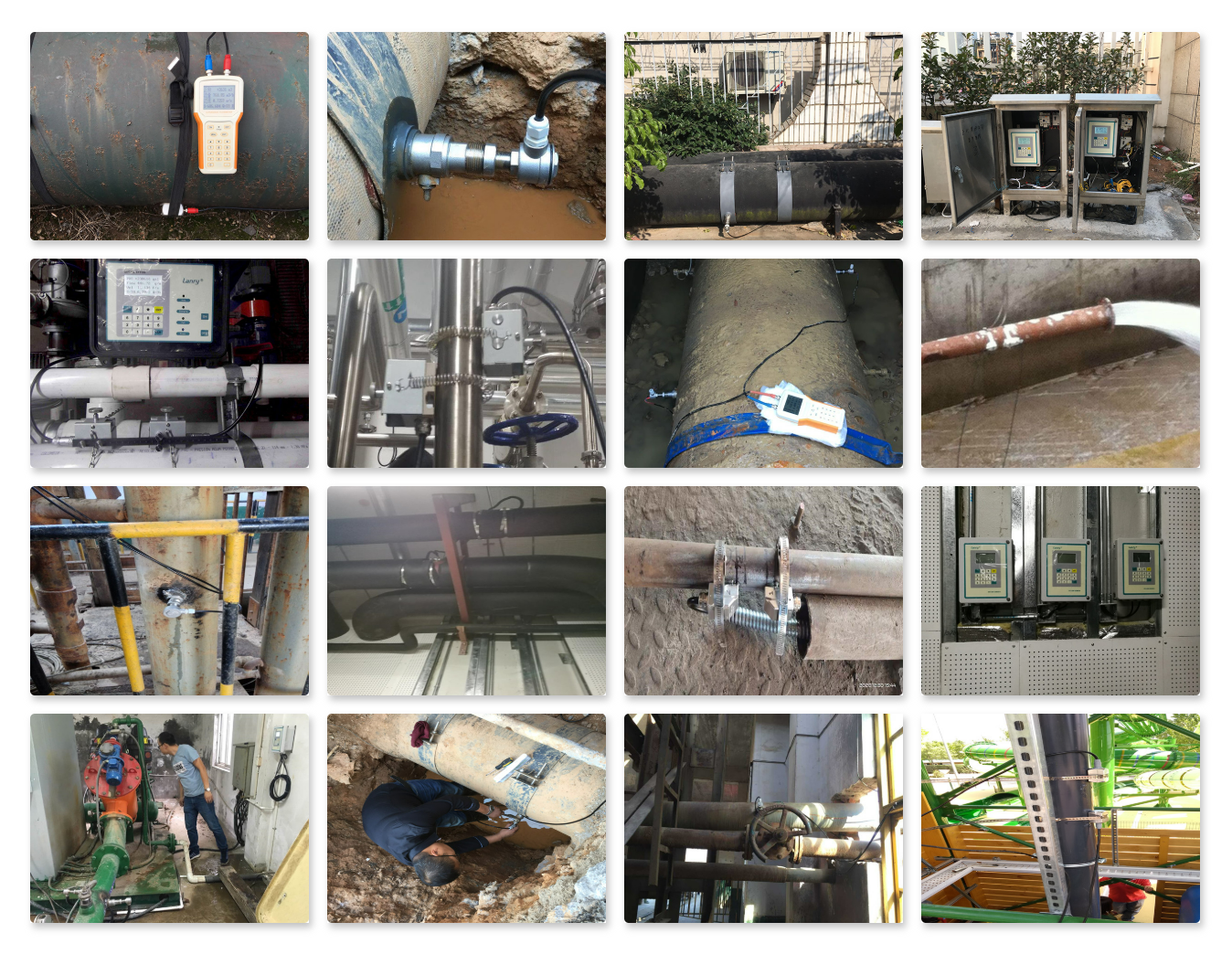

Ultrasonic flowmeters are widely adopted in various industries for their non - invasive nature, high accuracy, and ability to measure flow rates of a wide range of fluids. However, the performance of ultrasonic flowmeters can be significantly influenced by the properties of the pipe linings. This article explores how different pipe lining materials impact the operation and accuracy of ultrasonic flowmeters.

2. Working Principle of Ultrasonic Flowmeters

Ultrasonic flowmeters operate on the principle of measuring the time difference between ultrasonic signals traveling upstream and downstream in a fluid. Transit - time ultrasonic flowmeters measure the time taken for ultrasonic waves to travel in both directions. The flow velocity of the fluid is calculated based on this time difference. Doppler ultrasonic flowmeters, on the other hand, rely on the Doppler effect. They measure the change in frequency of ultrasonic waves reflected from particles or bubbles in the flowing fluid.

3. Impact of Pipe Lining Materials

3.1 Metallic Linings

Metallic linings, such as stainless - steel or aluminum, are highly reflective to ultrasonic waves. When ultrasonic signals encounter a metallic lining, a significant portion of the wave energy is reflected back. This reflection can cause interference with the transmitted and received signals in ultrasonic flowmeters. For example, in industrial applications where pipes with metallic linings are used to transport corrosive fluids, the strong reflection from the lining may lead to inaccurate measurement of the time - of - flight or Doppler shift. As a result, the calculated flow rate may deviate from the actual value.

3.2 Rubber Linings

Rubber linings are known for their flexibility and good corrosion - resistance. However, they have relatively high acoustic attenuation. Ultrasonic waves lose a substantial amount of energy as they pass through rubber linings. This attenuation can reduce the signal - to - noise ratio in ultrasonic flowmeters. In systems with thick rubber linings, the received ultrasonic signals may be too weak to accurately measure the flow parameters. For instance, in wastewater treatment plants where pipes with rubber linings are common, the excessive attenuation of ultrasonic waves can lead to measurement errors, especially when measuring low - flow rates.

3.3 Plastic Linings

Plastic linings, like polyethylene (PE) and polyvinyl chloride (PVC), exhibit different acoustic properties. Some plastics have a relatively low acoustic impedance, which can cause significant refraction of ultrasonic waves at the interface between the pipe wall and the lining. This refraction can distort the path of the ultrasonic signals, making it difficult for the flowmeter to accurately measure the time - of - flight or Doppler shift. In addition, plastic linings may absorb a certain amount of ultrasonic energy, further reducing the signal strength. For example, in irrigation systems using PVC - lined pipes, the refraction and absorption of ultrasonic waves by the lining can lead to inaccurate flow measurements.

3.4 Ceramic Linings

Ceramic linings are often used in high - temperature and abrasive environments due to their excellent wear - resistance and high - temperature stability. However, ceramic materials have a high acoustic impedance, which can cause strong reflection of ultrasonic waves. Similar to metallic linings, the reflection from ceramic linings can interfere with the normal operation of ultrasonic flowmeters. In industries such as mining and cement production, where pipes with ceramic linings are used to transport abrasive slurries, the strong reflection of ultrasonic waves from the ceramic lining can result in unreliable flow measurements.

4. Mitigation Strategies

To minimize the impact of pipe linings on ultrasonic flowmeters, several strategies can be adopted. One approach is to select the appropriate type of ultrasonic flowmeter based on the properties of the pipe lining. For example, in pipes with highly reflective linings, Doppler - type ultrasonic flowmeters may be more suitable as they are less affected by signal reflection. Another strategy is to optimize the installation of the flowmeter. This includes ensuring proper alignment of the ultrasonic transducers and selecting the appropriate installation location to minimize the impact of lining - related signal distortion. Additionally, advanced signal processing techniques can be employed to enhance the accuracy of flow measurements in the presence of pipe linings.

5. Conclusion

The material of pipe linings plays a crucial role in the performance of ultrasonic flowmeters. Different lining materials, such as metallic, rubber, plastic, and ceramic, can have various effects on ultrasonic signals, including reflection, attenuation, and refraction. Understanding these impacts and implementing appropriate mitigation strategies are essential for ensuring accurate and reliable flow measurements in industrial applications. By carefully considering the properties of pipe linings and selecting the right ultrasonic flowmeter and installation method, industries can optimize the performance of their flow measurement systems.

Post time: Apr-08-2025