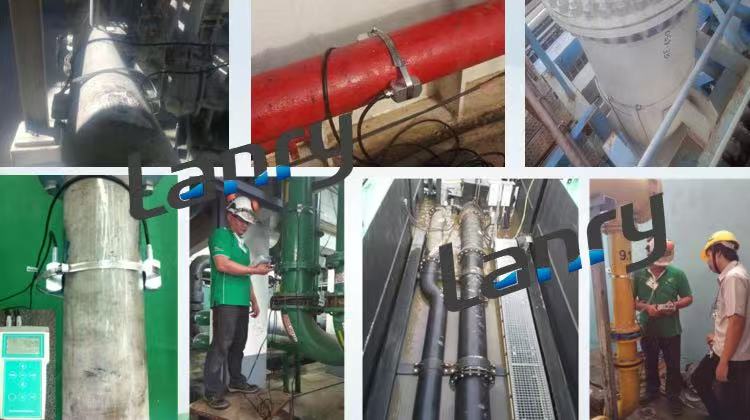

Doppler flowmeter sensors are widely used for measuring the flow rate of fluids, especially those with suspended particles or bubbles. Proper installation of these sensors is crucial to ensure accurate and reliable measurements. This article will introduce several common installation methods and key considerations.

Pipe Mounting

Through - Pipe Installation

- Sensor Selection: First, select a suitable Doppler flowmeter sensor based on the pipe diameter, fluid type, and expected flow range. For larger pipes, sensors with a wider beam angle may be required to cover the entire cross - section of the fluid flow.

- Pipe Surface Preparation: Clean the outer surface of the pipe where the sensor will be installed. Remove any dirt, rust, or paint to ensure good acoustic contact. Rough surfaces can scatter ultrasonic signals, leading to inaccurate measurements.

- Sensor Attachment: Use a coupling agent, such as ultrasonic gel or special adhesive, to attach the sensor to the pipe. This helps transmit ultrasonic signals effectively. Secure the sensor firmly in place using brackets or clamps, ensuring it remains in the correct position during operation.

In - Line Installation

- Pipe Cutting and Fitting: Cut a section of the pipe to install the Doppler flowmeter sensor assembly. Weld or flange - mount the sensor housing into the pipeline. Make sure the installation is in a straight section of the pipe, away from elbows, valves, or other fittings that can disrupt the flow profile.

- Sensor Alignment: Align the sensor's ultrasonic beam with the direction of fluid flow. Incorrect alignment can result in significant measurement errors. Use alignment tools or follow the manufacturer's guidelines to ensure proper orientation.

Submersible Installation

Water Body Deployment

- Sensor Preparation: Waterproof the Doppler flowmeter sensor if it is not already designed for submersible use. Ensure all electrical connections are properly sealed to prevent water ingress.

- Deployment Location: Select an appropriate location in the water body, such as a river, lake, or wastewater treatment tank. Avoid areas with strong turbulence, vortices, or near the inlet or outlet of the water system, as these can affect the accuracy of the measurements.

- Mounting and Anchoring: Mount the sensor on a stable platform or structure. Use ropes, chains, or stakes to anchor the sensor in place, preventing it from moving due to water currents.

Considerations for Installation

Flow Profile and Velocity

Understand the flow profile and velocity of the fluid before installation. The Doppler flowmeter's performance can be affected by non - uniform flow, so it's best to install the sensor in a section of the pipe or water body where the flow is relatively stable and laminar.

Electrical and Signal Interference

Keep the sensor's electrical cables away from sources of electromagnetic interference, such as power lines, motors, or other electrical equipment. Use shielded cables and proper grounding to minimize interference and ensure accurate signal transmission.

Maintenance Access

Ensure that the installed sensor is easily accessible for maintenance, calibration, and replacement. This may involve leaving enough space around the sensor and providing proper access points.

Proper installation of Doppler flowmeter sensors is essential for obtaining accurate and reliable flow measurements. By following the appropriate installation methods and considering the key factors, users can maximize the performance of these sensors in various applications.

Post time: Apr-01-2025