Doppler ultrasonic flowmeters, based on the Doppler Effect Principle, have found extensive applications in multiple fields due to their unique measurement capabilities.

The Doppler Effect Principle lies at the heart of these flowmeters. When an ultrasonic wave is transmitted into a flowing fluid that contains particles or bubbles acting as scatterers, the frequency of the wave reflected from these moving scatterers experiences a shift. This frequency shift is directly related to the velocity of the fluid, allowing for the accurate calculation of the flow rate.

One of the most prominent applications is in measuring the flow of dirty liquids. In industries like wastewater treatment, the fluid is filled with various impurities and suspended solids. The Ultrasonic Doppler Flowmeter for Dirty Liquids proves to be highly effective here. For example, in a large - scale wastewater treatment plant, it can continuously monitor the flow of sewage, providing crucial data for treatment process optimization. This ensures that the treatment plant operates efficiently, reducing the environmental impact of untreated wastewater.

Dual - Sensor Doppler Ultrasonic Flowmeters are also gaining popularity. The presence of two sensors improves the accuracy and reliability of the measurement. In industrial applications where precise flow control is essential, such as in chemical manufacturing plants, these dual - sensor flowmeters can accurately measure the flow of different chemical substances. This helps in maintaining the correct proportions of reactants in chemical processes, which is vital for product quality and production efficiency.

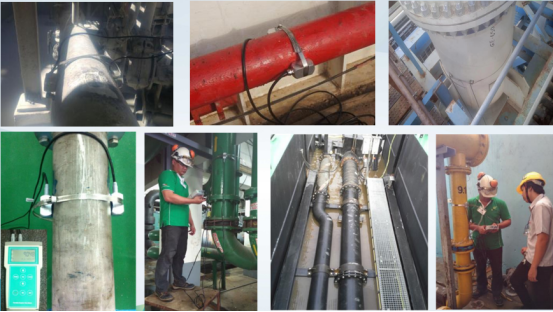

When it comes to installation, Doppler Ultrasonic Flowmeter Installation is relatively straightforward in many cases. Their non - invasive or minimally invasive installation methods make them suitable for a wide range of pipelines. For instance, in existing water supply pipelines, they can be installed without the need for major pipeline modifications, minimizing disruption to the water supply service.

However, to ensure accurate measurement, proper Doppler Ultrasonic Flowmeter Calibration Method must be followed. Regular calibration, using known flow standards, helps to correct any potential errors in the measurement. This is crucial for maintaining the high - accuracy performance of the flowmeter over time, especially in applications where precise flow data is required, like in pharmaceutical manufacturing.

There are several Doppler Ultrasonic Flowmeter Accuracy Factors. The properties of the fluid, such as its viscosity and the size and concentration of scatterers, can affect the accuracy. Additionally, the installation location and the quality of the sensors also play important roles. Understanding and controlling these factors can significantly improve the measurement accuracy.

In industrial applications, Doppler ultrasonic flowmeters are used in a variety of scenarios. In oil and gas pipelines, they can measure the flow of crude oil or natural gas, providing essential data for production monitoring and revenue metering. In power plants, they help in measuring the flow of cooling water, ensuring the efficient operation of the power - generation equipment.

Portable Doppler Ultrasonic Flowmeter Features make them convenient for on - site inspections and temporary measurement needs. Technicians can easily carry them to different locations to check the flow rate. For example, during the maintenance of industrial facilities, these portable devices can quickly assess the flow conditions in various pipelines.

The Doppler Ultrasonic Flowmeter Signal Analysis is a complex but crucial process. Sophisticated algorithms are used to analyze the received signals, separating the useful flow - related information from noise. This advanced signal analysis ensures the reliability of the flow measurement results.

Finally, a proper Doppler Ultrasonic Flowmeter Maintenance Guide is essential. Regular maintenance, including cleaning the sensors, checking for any physical damage, and updating the software if necessary, can extend the lifespan of the flowmeter and maintain its high - performance operation.

In conclusion, Doppler ultrasonic flowmeters, with their wide - ranging applications and unique features, have become an indispensable part of modern fluid flow measurement in numerous industries, contributing to efficient production, quality control, and environmental protection.

Post time: Feb-10-2025