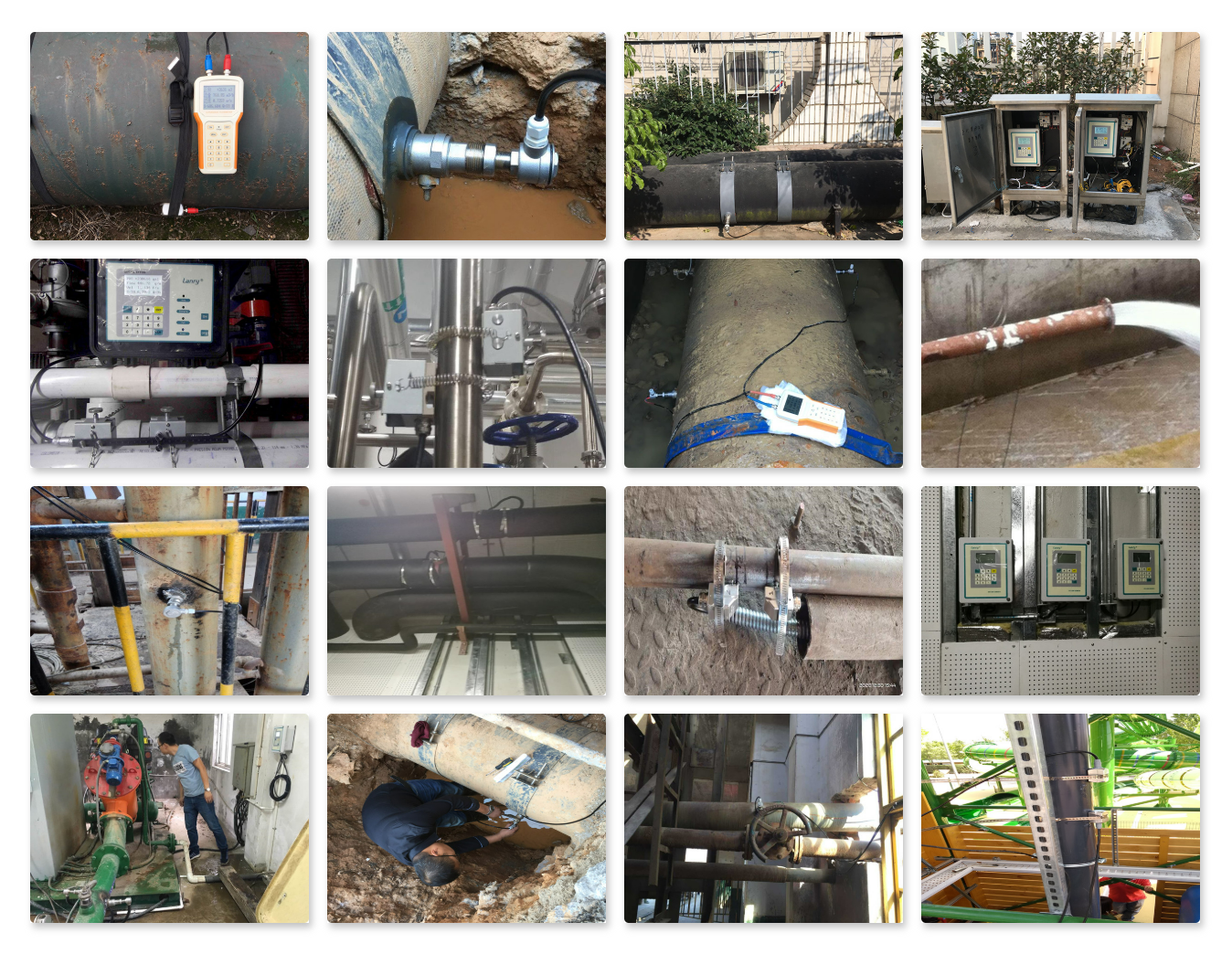

Transit-time ultrasonic flowmeters are advanced devices that utilize the principle of sound wave propagation to accurately measure the flow rate of liquids. These flowmeters are particularly valuable in situations where modifying pipelines for installation is impractical, offering a non-intrusive method of flow measurement. By measuring the time difference it takes for sound waves to travel through the fluid, these flowmeters can precisely determine the flow velocity, and from there, calculate the flow rate. This technology is extensively used in various industries, including water treatment, chemical processing, and environmental monitoring. In this article, we will explore the working principle of transit-time ultrasonic flowmeters and their diverse applications in the field of liquid measurement.

1. The Working Principle of Transit-Time Ultrasonic Flowmeters

The fundamental working principle of transit-time ultrasonic flowmeters is based on measuring the time it takes for an acoustic signal (sound wave) to travel through the liquid. When a sound wave is emitted by a transducer, it travels through the flowing liquid at a speed influenced by the flow velocity. In a flowing liquid, the sound wave's propagation time is faster in the direction of the flow and slower in the opposite direction.

Typically, a transit-time ultrasonic flowmeter consists of two sensors or transducers installed on the pipeline. One transducer emits a pulse of sound, while the other transducer receives the signal after it has traveled through the liquid. By measuring the time difference between the sound wave traveling downstream and upstream, the flowmeter can calculate the flow velocity. With the known pipe cross-sectional area, the flow rate can then be determined.

2. Applications of Transit-Time Ultrasonic Flowmeters

Transit-time ultrasonic flowmeters are widely used in liquid flow measurement, especially in industries that require precise flow measurement. Some key areas of application include:

1. Water Treatment Industry

In water treatment processes, transit-time ultrasonic flowmeters are employed to measure the flow of clean water and wastewater. These flowmeters are particularly useful in environments where traditional flow meters may struggle, such as in pipes with debris, air bubbles, or irregular flow patterns. Their ability to deliver accurate and stable measurements ensures the effective management of water resources and compliance with environmental standards.

2. Chemical Industry

The chemical industry deals with a variety of corrosive, abrasive, or viscous fluids. Transit-time ultrasonic flowmeters are ideal for measuring these fluids, as they have no moving parts that could wear out or corrode. Furthermore, these flowmeters can provide reliable measurements even under fluctuating temperatures and pressures, which are common in chemical processes.

3. Oil and Gas Industry

In the oil and gas sector, transit-time ultrasonic flowmeters are widely used to measure the flow of oil, gas, and other fluids in pipelines. These flowmeters are particularly beneficial for long-distance pipelines, where the installation of traditional flow meters can be difficult and costly. The ability of transit-time ultrasonic flowmeters to operate accurately under high pressure and temperature conditions makes them a critical tool in the industry.

4. Food and Beverage Industry

In the food and beverage industry, precise measurement of liquid flow is essential for maintaining consistent product quality. Transit-time ultrasonic flowmeters are often used to measure the flow of liquids like milk, juices, and syrups. Since they do not require direct contact with the fluid, these flowmeters help maintain hygienic conditions while ensuring accurate flow measurement.

5. Environmental Monitoring

Transit-time ultrasonic flowmeters play a crucial role in environmental monitoring, particularly in the management of wastewater and stormwater. By accurately measuring water flow in rivers, canals, and treatment plants, these flowmeters help authorities monitor and manage water quality, ensuring effective treatment and preventing contamination.

3. Advantages of Transit-Time Ultrasonic Flowmeters

Transit-time ultrasonic flowmeters offer several advantages over traditional mechanical flowmeters, making them ideal for a wide range of applications:

1. Non-Intrusive Measurement

Since transit-time ultrasonic flowmeters use external sensors and do not require direct contact with the liquid, they are perfect for measuring corrosive, abrasive, or contaminated fluids. This non-intrusive nature also eliminates the risk of contamination, making them suitable for industries where hygiene is critical, such as food and pharmaceuticals.

2. High Accuracy

By measuring the time difference between sound waves traveling with and against the flow, transit-time ultrasonic flowmeters provide highly accurate measurements of flow velocity. This enables precise calculation of flow rates, even for complex or fluctuating fluid conditions.

3. Easy Installation

Transit-time ultrasonic flowmeters are typically clamp-on devices that can be easily mounted on the exterior of existing pipelines, requiring no interruption to fluid flow. This makes installation straightforward, minimizing downtime and reducing costs compared to other flow measurement methods that require pipeline modifications.

4. Versatility in Harsh Environments

These flowmeters can operate in challenging environments, including high-pressure, high-temperature conditions, and with fluids containing solids or gases. This versatility makes them ideal for applications in industries like oil and gas, chemicals, and wastewater treatment.

5. Low Maintenance

Because transit-time ultrasonic flowmeters have no moving parts, they require minimal maintenance and have a longer lifespan compared to traditional mechanical flowmeters, which can be prone to wear and tear.

4. Future Trends

As industrial automation and digital technologies continue to evolve, the capabilities of transit-time ultrasonic flowmeters are also expanding. The integration of these flowmeters with IoT (Internet of Things) devices, data analytics, and cloud-based systems is expected to provide real-time monitoring and predictive maintenance capabilities. This will further enhance operational efficiency and reduce downtime across various industries. Additionally, advancements in sensor technology may improve the accuracy and range of these devices, making them even more versatile and reliable.

Conclusion

Transit-time ultrasonic flowmeters are a reliable and non-intrusive solution for accurately measuring liquid flow in a wide range of industries. Their ability to measure corrosive, viscous, or contaminated fluids without requiring direct contact makes them ideal for applications in water treatment, chemicals, food and beverage, and environmental monitoring. With their high accuracy, easy installation, and low maintenance, transit-time ultrasonic flowmeters are set to continue playing a crucial role in the optimization of industrial processes and resource management. As technology advances, these flowmeters will become even more integral to ensuring efficiency, sustainability, and safety in industrial operations.

Post time: Feb-10-2025