In the world of flow measurement, precision and reliability are key, and Doppler Ultrasonic Flow Meters are at the forefront of this technology. These advanced instruments use Doppler technology to measure the velocity of liquids, gases, and other fluids flowing through pipes or open channels. As industries look for solutions that ensure higher accuracy, real-time monitoring, and non-invasive measurement, Doppler ultrasonic flow meters have become a critical tool for various applications.

1. What is a Doppler Ultrasonic Flow Meter?

Doppler Ultrasonic Flow Meter is a type of non-invasive flow meter that uses sound waves to measure the flow of liquids or gases. By emitting ultrasonic pulses and measuring the frequency shift caused by the Doppler effect, these meters can accurately calculate the velocity of the fluid moving through a pipe. This method eliminates the need for physical contact with the fluid, ensuring no interference with the flow and no risk of contamination.

2. How Does Doppler Ultrasonic Flow Measurement Work?

Doppler ultrasonic flow meters rely on the Doppler effect, a phenomenon that occurs when the frequency of sound waves changes due to the movement of the fluid. The flow meter sends an ultrasonic pulse into the fluid, and the pulse bounces back after hitting particles or bubbles suspended in the fluid. The frequency shift of the returned pulse is directly proportional to the flow velocity, allowing accurate and real-time measurements without intrusive mechanical parts.

3. Advantages of Doppler Flow Meters for Liquids

Doppler flow meters are particularly effective for measuring liquids with particles or bubbles, such as slurries, wastewater, and even dirty or corrosive fluids. The Doppler flow meter for liquids works well in environments where other types of flow meters would struggle or require costly maintenance. Their ability to handle fluids with suspended solids makes them indispensable in industries like wastewater treatment, chemical processing, and mining.

4. Non-invasive Flow Measurement: A Game-Changer

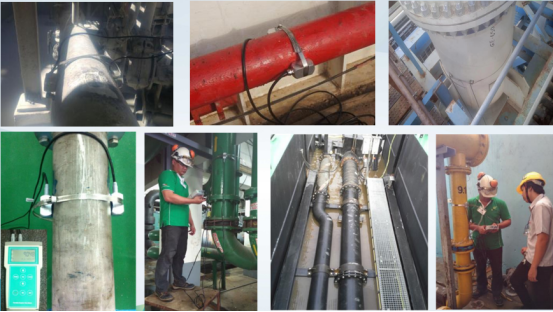

One of the standout features of non-invasive flow meters is that they do not require any penetration or direct contact with the fluid being measured. This is especially valuable in systems where the fluid could be hazardous, contaminated, or under high pressure. Doppler ultrasonic flow meters are mounted externally on the pipe, using acoustic waves to gather the necessary data. This means no need for pipe modifications, resulting in lower installation and maintenance costs.

5. Portable Doppler Flow Meters for Flexible Monitoring

For industries that require flexible, on-site testing and data logging, portable Doppler flow meters provide an excellent solution. These compact and easy-to-use devices are perfect for temporary installations or for performing spot checks on various pipelines or channels. The real-time flow monitoring capabilities of portable devices help operators troubleshoot problems and ensure optimal flow conditions across different systems.

6. High-Accuracy Flow Measurement in Complex Environments

One of the key benefits of Doppler ultrasonic technology is its high accuracy in flow measurement. Doppler ultrasonic flow meters can provide precise readings even in challenging environments, including fluctuating flow rates and varying pipe sizes. Their ability to accurately measure flow velocity ensures that users receive dependable data for process optimization, system design, and energy consumption management.

7. Doppler Flow Meters for Industrial Applications

Industries such as chemical processing, mining, water treatment, and energy generation rely on Doppler ultrasonic flow sensors for monitoring the flow of liquids and gases. These industries often deal with aggressive fluids, thick slurries, or fluids with varying compositions. Traditional flow meters might not be effective or could incur high maintenance costs in these conditions. Doppler flow meters, on the other hand, offer a robust and reliable solution for a wide range of industrial applications.

8. Real-Time Flow Monitoring for Enhanced Control

Real-time flow monitoring is crucial for maintaining efficiency and optimizing processes. Doppler ultrasonic flow meters provide continuous, accurate flow data that allows for timely adjustments. By integrating these flow meters into a larger control system, businesses can monitor fluid flow, detect leaks or abnormalities, and prevent downtime, all in real time. This capability plays a significant role in improving operational efficiency and reducing costs in industries that rely on liquid or gas flow.

9. Applications in Water Treatment and Wastewater Management

In wastewater treatment and water treatment plants, Doppler ultrasonic flow meters are invaluable tools. These meters are widely used to monitor the flow of raw water, effluent, and sludge. By accurately measuring the flow of water through pipes and open channels, they help ensure that treatment processes operate within optimal parameters, and assist in regulatory compliance by providing accurate flow data for reporting purposes.

10. Doppler Technology for Flow Measurement: A Future-Proof Solution

As industries continue to embrace Doppler technology for flow measurement, the future of flow metering looks even more promising. With advancements in ultrasonic sensor technology, Doppler flow meters are becoming more sophisticated, with enhanced data logging, wireless communication capabilities, and better integration with automation systems. This evolution makes Doppler ultrasonic flow meters an even more indispensable part of industrial monitoring and control systems.

In conclusion,Doppler ultrasonic flow meters are transforming how industries measure and manage fluid flow. With their ability to measure flow with high accuracy, without contact with the fluid, and in challenging environments, they provide unparalleled value in a wide range of industries. Whether you’re monitoring water treatment systems, industrial processes, or environmental conditions, Doppler ultrasonic flow meters offer a reliable, cost-effective solution for modern flow measurement.

Post time: Dec-25-2024